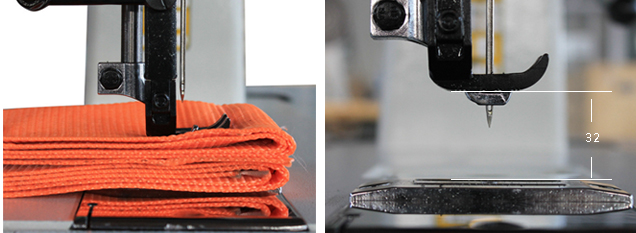

特點:適合中厚料縫制物的縫制作業,尤為適合0號至00號的粗線縫制���;采用連桿式天秤,獲得平整均一的線跡��;壓腳配合下送料機構作同步提升,極厚的材料也能輕松送入����;壓腳膝控提升高度32mm,方便極厚縫制物通過��;采用半回轉大型擺梭,減少底線交換頻度,提高作業效率�;工作空間420mm,方便厚料大型縫制物的進出回轉���;針距大12mm���;配置調節簡單的手柄式倒縫裝置�。

Characteristics:It is suitable for sewing thick material, especially for thick threads of No. 0 to No. 00.It adopts connecting rod tower crane, so it has smooth and even stitches.

The feeding mechanism assorted with presser could lift synchronous, so it could sew super-thick material.The lifting height of knee control presser is 32mm, it is easy for super-thick material to pass.It adopts semi-rotative big oscillating shuttle, which could reduce the changing times of bobbin thread and improve the working efficiency.The working space is 420mm, which is convenient for thick and large sewing material pass and rotation.The maximum needle gauge 12mm Equipped with handle back sewing unit, which could be regulated simply.

用途:適用于制鞋�����、沙發�、集裝袋�、安全帶����、皮革����、牛仔服���、帳篷等粗線厚料制品�。

Uses:Suitable for sewing of shoes, sofa, packing bags, safety belt and rents.

主要技術參數Main Parameters:

針數 Needles |

單針 Single needle |

縫速高達 Max.Sewing speed |

700針/分 needles/min |

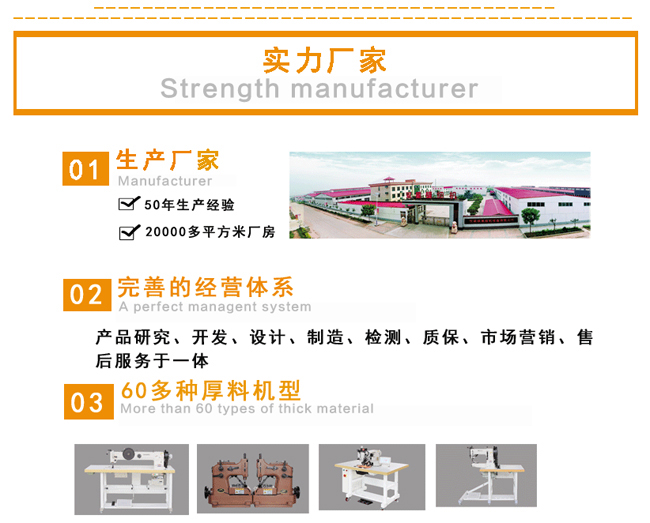

壓腳提升 Presser food lift |

手提 By hand |

13毫米 mm |

| 膝控 By knee |

32毫米 mm |

針桿行程 Needle bar stroke |

78毫米 mm |

機針 Needle size |

8×200/250/300 |

擺梭 Oscillating shuttle |

半回轉大型擺梭 semi-rotaive big oscillating shuttle |

壓腳交替上升量 Aiternating lifting distance of presser |

5~7毫米(標準6毫米) 5~7mm(Standard 6mm) |

潤滑方式 Lubrication |

手動潤滑 Manual |

作業空間 Operating room |

420×230毫米 mm |

電機 Motor |

550W 1400轉/分 r.p.m |

機頭重量 Machine head weight |

105kg kg |